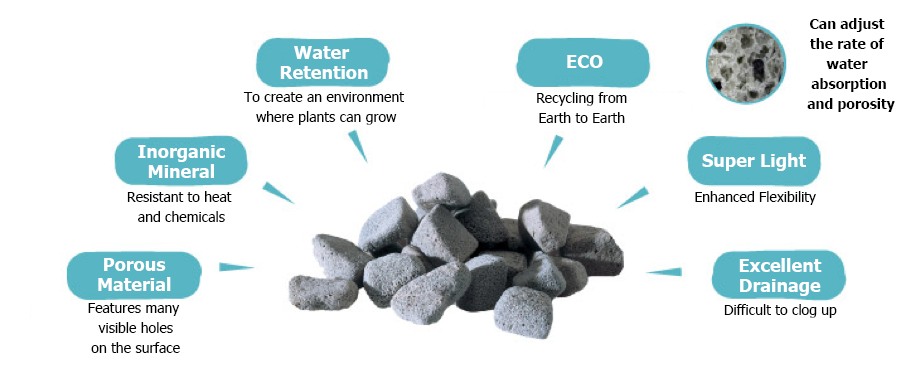

Supersol, which is an artificial porous-lightweight-foaming material (pumice) produced by crushing, baking and foaming the waste glass, is environmentally friendly soil-restoration-type material, and is excellent at water permeability and retention as well as fire proof.

Also in production process, super sol is utilized in many purposes, such as greening, insulation, horticulture, water purification, construction, civil engineering by controlling specific gravity and absorption rate according to the purposes. Supersol is a high value-added product which plays an inevitable role in forming resource recycling society.

Soil restoration

Environmentally friendly and perfect recycling type from earth to earth. In terms of renovation construction, super sol is treated as same as surplus soil treatment.

Water permeability and retention

Excellent drainage even when compaction. It is excellent at water permeability and retention as well as breathability, facilitating the growth of vegetation.

Incombustible

Because super sol is made of glass, it is inorganic material and fire-resistant. It also has a feature that is resistant to chemicals.

Execution capacity (High degree of freedom)

Super sol has high degree of freedom in construction site. Super sol can be used in any construction condition no matter how distorted the terrain is or there is underground pipe. Due to its lightweight, supersol is easily handled and makes execution possible even under rainy condition.

- Very light(3~4kN/m3)

- It is easily handled as embankment material and executable by normal execution procedures.

- No culture period.

- It is made of recycled glass bottle and does not elute hazardous subsistence, leading to high security for surrounding environment.

- It is inorganic mineral, thus chemically stable and no corrosion.

Lightweight (controllable specific gravity)

Specific gravity of super sol can be controllable according to the use.

Changing the additive mixture and baking condition, various products with different quality can be made.

| Standard | Specific gravity in absolutely dry condition | Absorption rate | Characteristic | Use |

| L1 | 0.25〜0.5 | 20% More than | Open-cell-foam-type super lightweight material with high water retention | Greening: drainage base material/Artificial lightweight soil/soil improved material Horticulture: Improved material for soil/pot bottom stone Agriculture: soil improved material/culvert drainage material Livestock: Anti-slip material for cattle sheds |

| L2 | 0.35〜0.5 | 20% Less than | Closed-cell-foam-type super lightweight material with strength | Civil engineering: lightweight embankment material/retaining wall backfill/Bridge abutment backfill material/embankment on underground structures/embankment material on soft ground/sandwich construction method (combination with crushed stone) Agriculture: culvert drainage materials |

| L3 | 0.5〜1.0 | 10% Less than | Almost closed pore-type lightweight material | Horticulture: hydroculture material Water tank: Filtration materials Disaster: Lightweight sandbags (for emergency level adjustment) |

| L4 | 1.0〜1.6 | 5% Less than | Closed-cell-foam-type material that nearly sinks in water | Civil engineering: backfill material for the rear of earthquake-resistant wharf/lightweight embankment material less than HW level Livestock: Water quality purification material/farming pond filter material |

Process of development

With regards to the implementation of demonstration test (research and development/demonstration test regarding technology for multi purposes use of waste glass) regarding the use expansion of glass bottle cullet, which is one of “support researches for practical use of recycling technology” that © Clean Japan Center (CJC) accepts from New Energy and Industrial Technology Development Organization (NEDO), “Super sol” production technology was developed by making a “research and development cooperation agreement” between Kishimoto international technology research, Co., Ltd. and CJC on February 1997 as a supplementary budget granted business by Minister of Economy, Trade and Industry.

After that, based on the research result, Trim Co., Ltd. developed the production device and put it into practical use. Currently, Trim introduces the plant throughout the country and expands “the local revitalization” through recycling.

Component table/data

Component table

| Ingredient | Content (%) | |

| SiO2 | Silicon dioxide | 73.5% |

| CaO | Canxidium Oxide | 12.1% |

| Na2O | Sodium oxide | 10.5% |

| Al2O3 | Aluminium oxide | 1.57% |

| K2O | Potassium oxide | 0.98% |

| MgO | Magnesium oxide | 0.42% |

Characteristic of ingredient

| Simple substance | Specific gravity (absolute density) | 0.25 to 0.5mg/m³ |

| Particle diameter range | 2 to 75mm | |

| Water absorption | Less than 20% | |

| Strength of Unconfined compression | 30 to 40kgtflcm² | |

| Heavy metal elution | Not included | |

| During compaction | Density | 0.3 to 0.4t/m² |

| Strength of Triaxial compression | φ=30° More than | |

| CBR Value | 17.70% | |

| Coefficient of Water Permeability | 3×10-2 to 1×10°cm/s |

Design constant

| Dry density (t/m³) | Design constant | Laying leveling thickness 30cmのnumber of compaction(time/layer) | ||||

| Wetting density (t/m³) | Adhesive force (kN/m²) | Angle of internal friction (degree) | Permissible instruction capacity (kN/m²) | Level 10t marsh of bulldozer | Level 1t vibration roller | |

| 0.25 | 0.4 | 0 | 25 | 39 | 0 | 0 |

| 0.3 | 0.45 | 30 | 98 | 2 | 4 | |

| 0.35 | 0.55 | 137 | 4 | 8 | ||

| 0.4 | 0.6 | 176 | 8 | - | ||

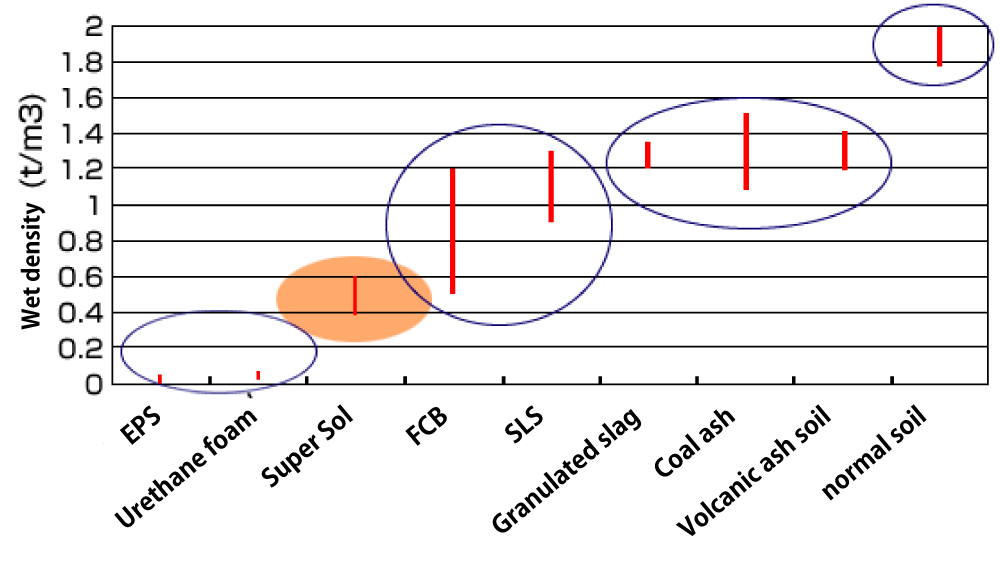

Types of lightweight embankments

| Classification | lightweight banking materia | Wet density (t/m³) | Feature | |

| The method of using lighter weight materials | Artificial material | EPS | 0.01〜0.03 | Ultra- lightweight , self-supporting |

| Urethane foam | 0.03 grade | Ultra-light , liquidity | ||

| Generating material | Granulated slag | 1.2〜1.35 | Ironworks by-product | |

| Granulated slag 1.2〜1.35 Ironworks by-product Coal ash | 1.1〜1.5 | Thermal power plant by-products | ||

| Super Sol | 0.4〜0.6 | Manufactured from glass bottles | ||

| Volcanic ash soil | 1.2〜1.4 | Cheapness | ||

| The method according to the weight of the soil | manufacturing Method for foamed resin- mixed lightweight soil | FCB etc | 0.5〜1.2 | Liquidity, density adjustable |

| Foam beads mixed lightweight soil | SLS etc | 0.9〜1.3 | Density adjustable, close to the soil characteristics | |

Wet density of lightweight embankment